History of Security Inks Usage

The history of security inks is far more ancient than one might imagine, with the first mention of an invisible ink being used as a secret means of war time coming from the Greek writer Aeneas Tactcus in the 4th century BC. Philo of Byzantium, another Greek writer from antiquity, described an invisible ink comprising a reagent as far back as the 4th century BC. The Arabs started using lemons as organic inks in the 7th century AD as did the Europeans in the 16th century.

Science Behind Security Ink

Invisible Ink Demystified

What goes into creating security inks?

- Invisible

- Biometric

- Thermochromic

- Fluorescent

- Magnetic

- Optically variable

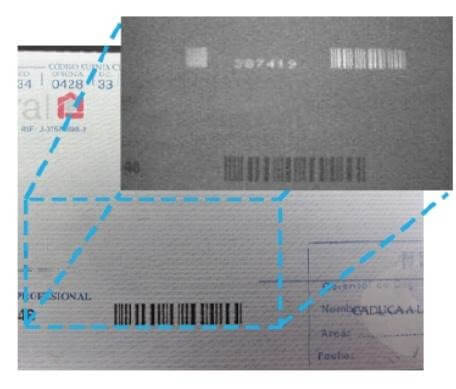

- Infrared

- Reactive

- Erasable

Security Ink Technologies

Biometric Taggants

Erasable Ink

Coin Reactive Ink

Bleeding Ink

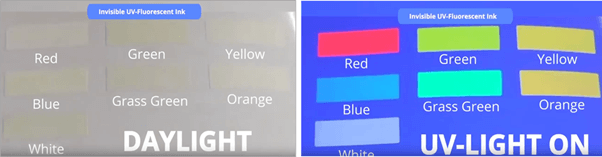

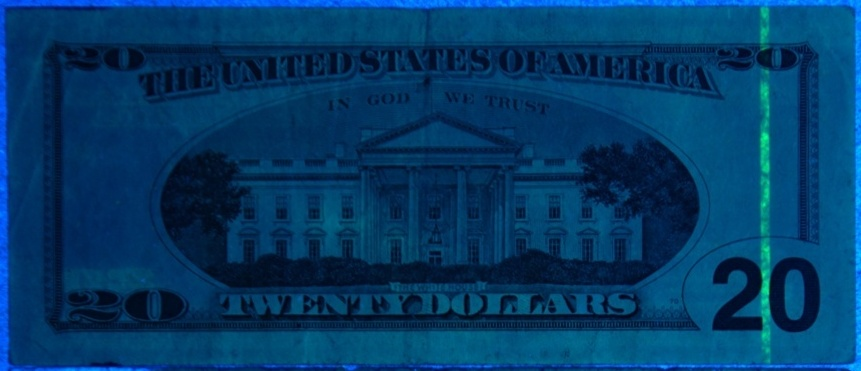

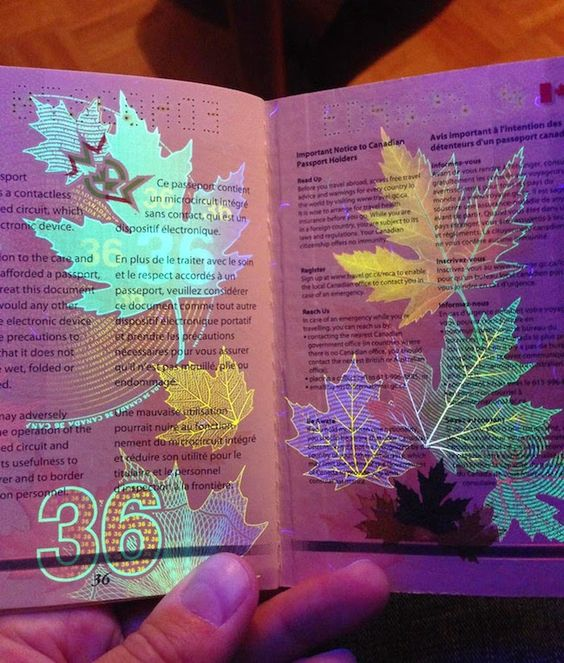

UV Invisible Fluorescent Ink

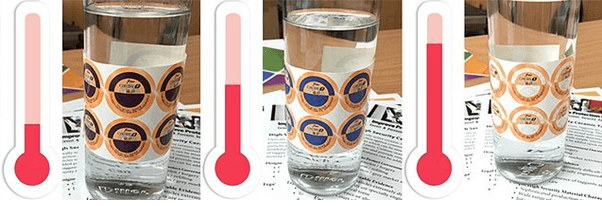

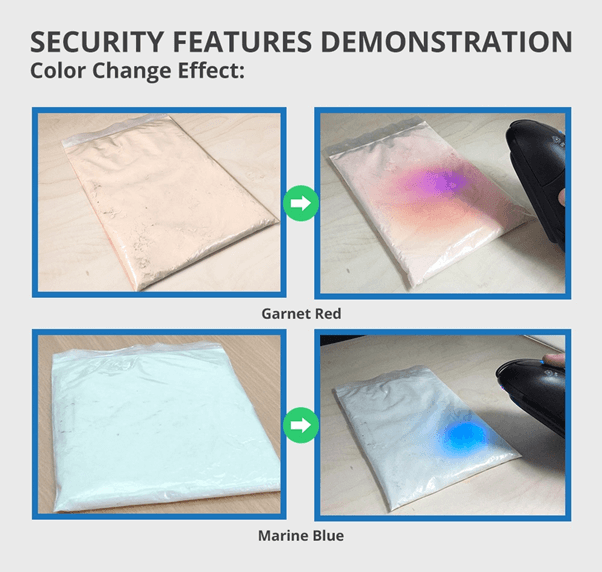

Thermochromic Ink

Fugitive Ink

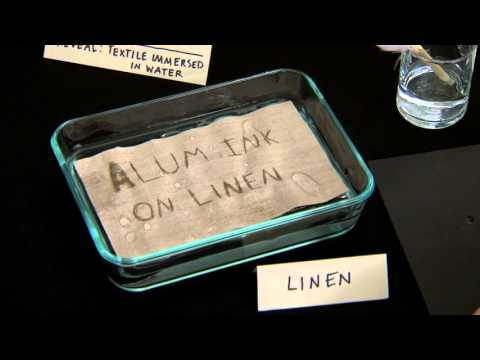

Chemical Reactive Inks

Optically Variable Ink

Magnetic Ink

Penetrating or Indelible Ink

Pen Reactive Ink

Secondary Fluorescing Ink

Photochromic Ink

Visible Infrared Ink

Metameric Inks

Adhesion Promotion Varnish

Security Ink Applications

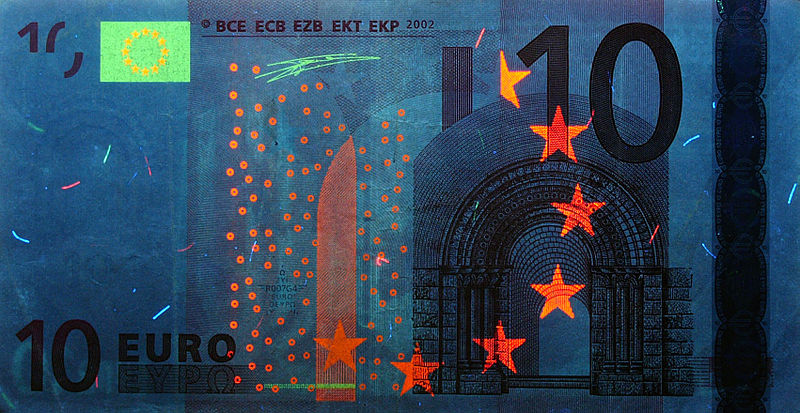

Bank Notes

Textiles

Packaging

Official Documents

Labels

Pharmaceuticals

Wines and Spirits

Handbags and Cosmetics

Concert, Sports and Lottery Tickets

Matrix-Mark™ Taggants: Enabling Next-Generation Security Inks

Transforming Ordinary Inks to Next-Gen Security Inks

Versatile Delivery Options

- Offset / lithographic ink

- Flexographic ink

- Silk screen ink

- Rotogravure ink

- Intaglio ink

- Inkjet ink

- Laser Toner

- Thermal transfer ribbon

- Plastic pellets for injection molding

- Clear coating

These taggants have the following properties:

- For all printing technologies: Offset, rotogravure, flexo, screen, intaglio, inkjet, laser, TTP, etc.

- Inorganic: No performance impact by age or exposure to strong UV radiation

- Tough: Sustained pressure even in intaglio printing process

- Chemical resistant: Withstood chemical resistant tests even for banknote use

- Temperature resistant: Melting point above 1000°C

- Small size: 500 nm to 5 micrometer (depending on application)– difficult to detect

- Complex formulation: Virtually impossible to re-engineer

- Involves proprietary well researched methods of forensic detection: Every taggant comes with a unique forensic feature that enables the trace element to be used as evidence in the court of law.

Matrix-Mark™ Taggant Security Features

Sophisticated covert feature (Level 3)

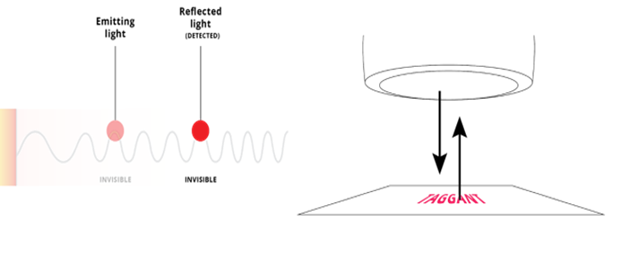

Detection principle: Invisible light from emitting device will be converted into another invisible light wavelength. The unique particle characteristics can only be detected with proprietary detection systems. Multiple taggant versions are available.

This is an advanced anti-counterfeit feature as it cannot be detected with ‘simple’ verification tools, e.g. UV light or IR laser pen.

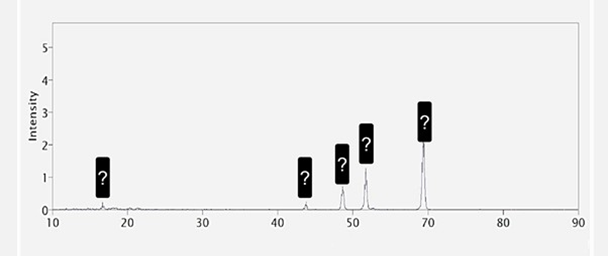

Forensic security feature (Level 4)

During production of the MatriX-Mark™ taggants a unique forensic feature can be added. A nearly infinitive number forensic signatures can be added to provide irrefutable proof of authenticity in court of law, beyond any reasonable doubt.

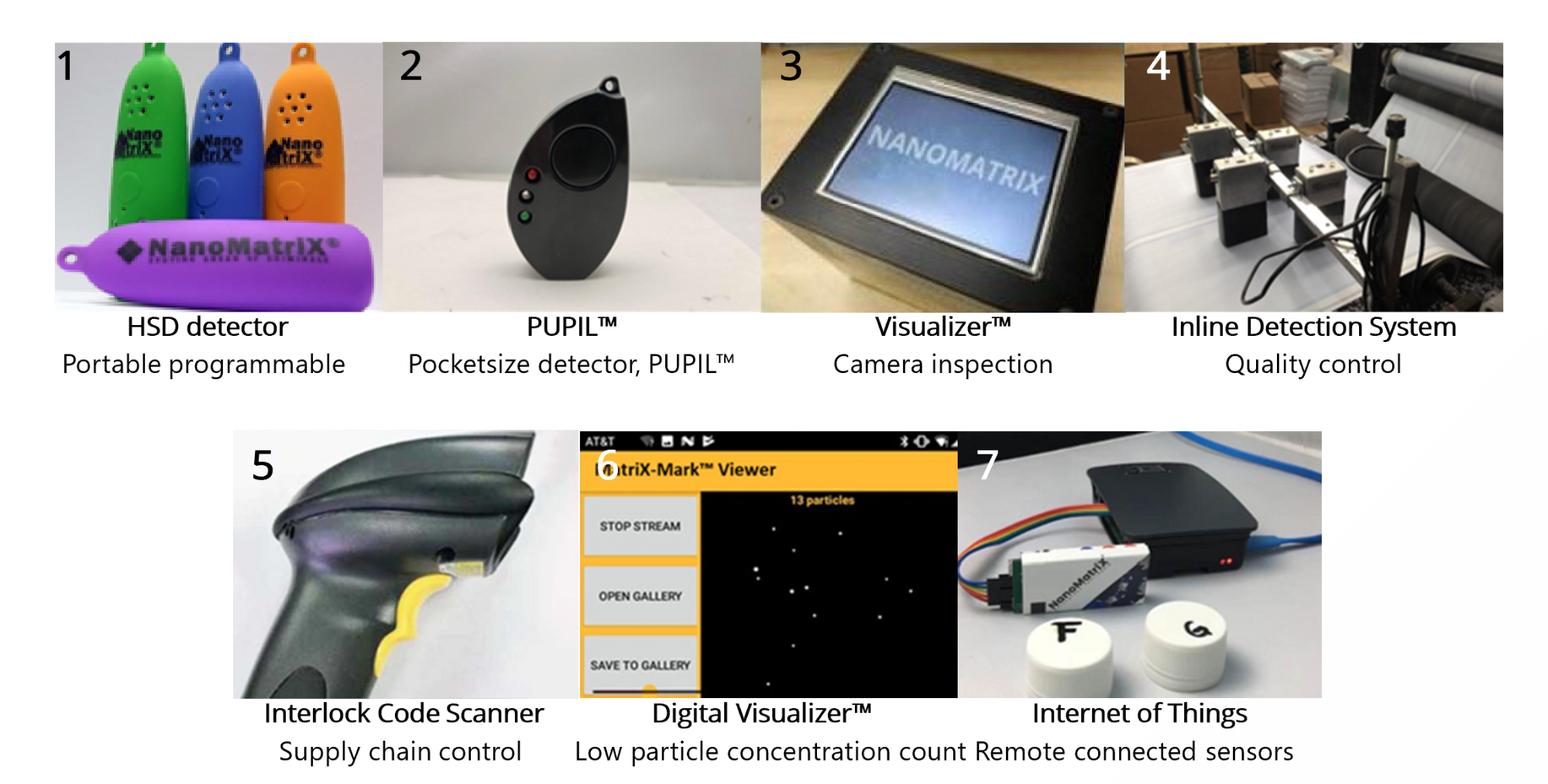

For detecting MatriX-Mark™ Taggants, handheld devices or in-field single- or multi-taggant detectors and similar inspection systems need to be used.

These specialized detectors and scanners carry out complex analyses before confirming the presence of a taggant version by giving a binary response. Different high-speed and fully automatic detection devices for locating the presence of security taggants in documents or products can also be used.

Enhance Product Authenticity and Traceability with MatriX-Mark™ Taggants

The inks with MatriX-Mark™ Taggants have already been successfully used in rotogravure, screen printing, flexo, intaglio, offset, and other printing methods. The high usability of these security taggant versions cements the fact that they can be seamlessly integrated into different products and production processes.

Strengthen product authenticity and traceability with next-generation security inks that are empowered by MatriX-Mark™ taggant technology.