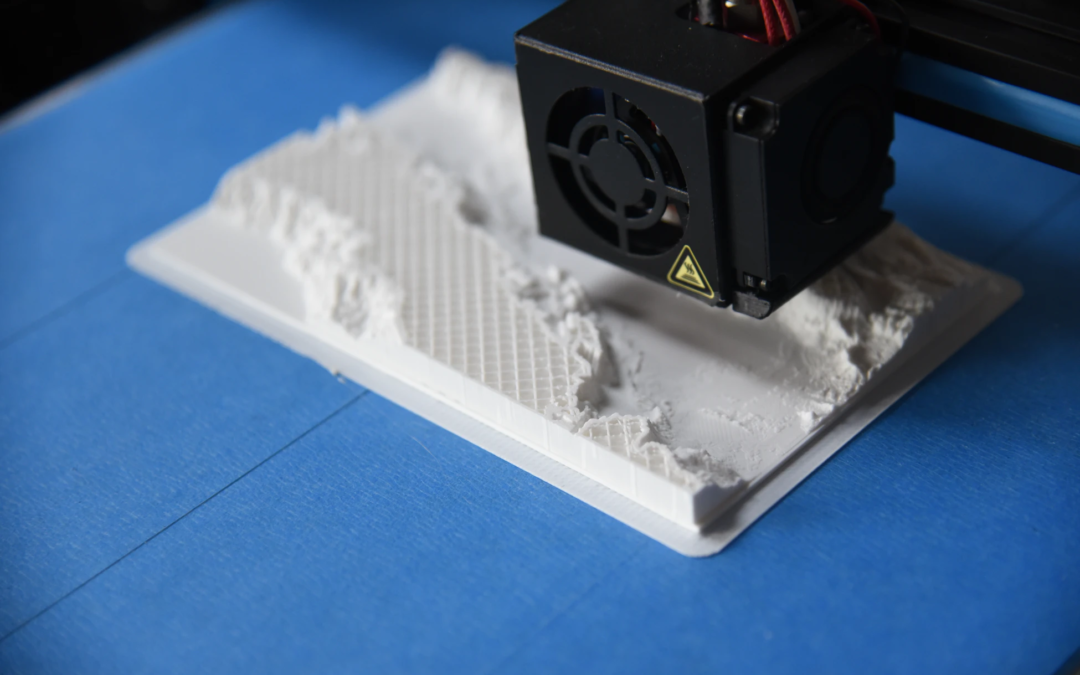

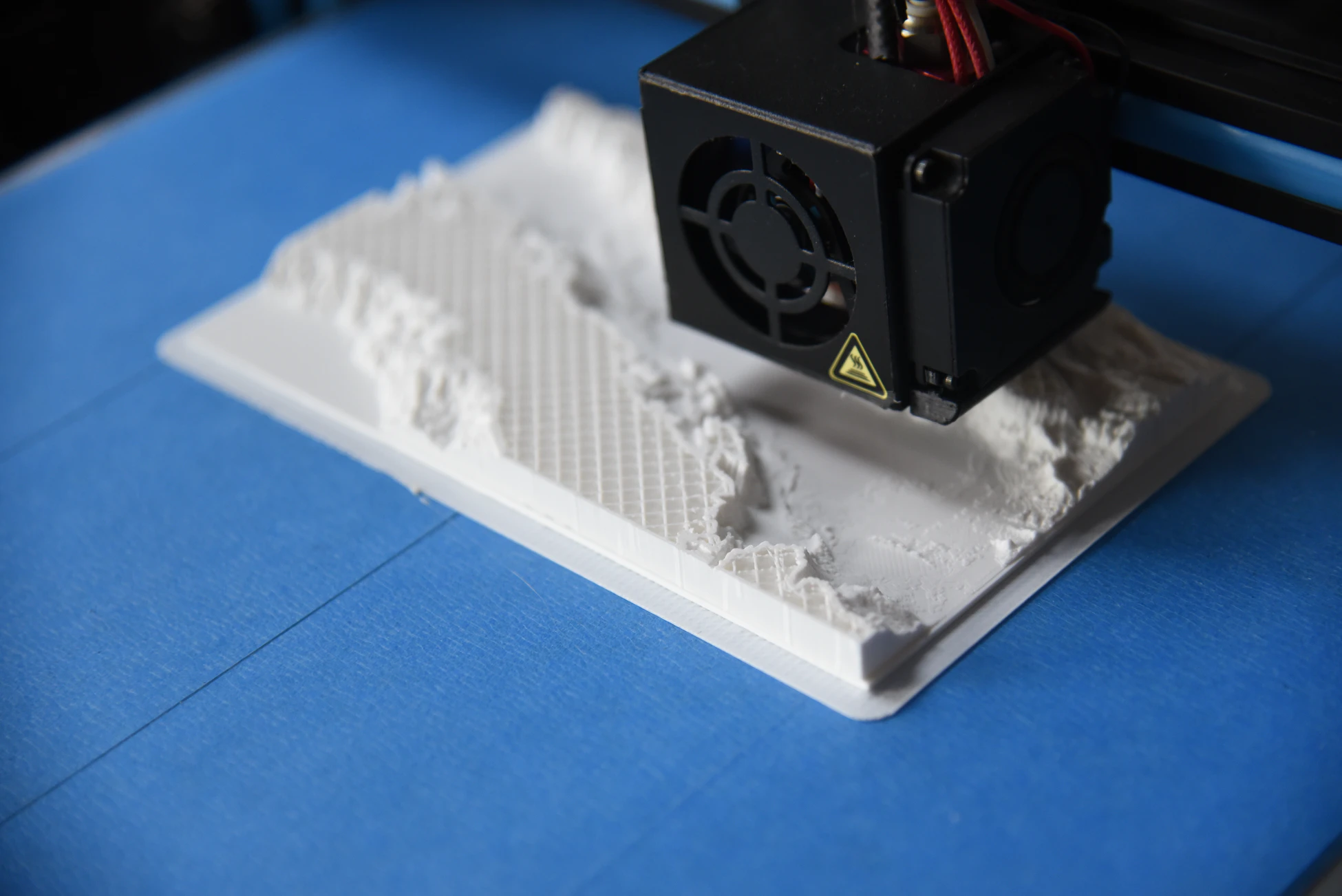

The invention of 3D printing surely ranks on top as one of the most innovative inventions that has revolutionized manufacturing across industries. The economies of scale and efficiencies introduced to any manufacturing process on account of the use of this technology is phenomenal.

But as with all cutting-edge disruptive technology, the advent of 3D printing has also given rise to multi-million dollar counterfeit schemes and products which harm big and small brands alike.

The widespread availability of cheap 3D printers, while proving to be a boon for the average consumer, has also led to the gross misuse of counterfeiters who use the technology to print fake products.

While the proliferation of 3D printing technology has imparted convenience, efficiency, and economical pricing to a whole range of products, the fact that it can also be misused on a large scale in counterfeiting activities gives industries across the world much to worry about.

The solution may not lie in overregulating the 3D printing industry, but to step up one’s brand security measures in an effective and comprehensive manner.

Industries like fashion, pharmaceutical, and consumer electronics are particularly vulnerable to the threat of 3D-printed fakes. It is quite easy for counterfeiters to obtain access to digital files carrying 3D-scanned images of products, which they can then reproduce at will. Equally at risk are trademark, patent, and design rights owners.

Problem of 3D Printed Fakes/Counterfeits

Among the problems expected to be faced by unsuspecting consumers are the purchase of cheap knock-offs being sold as genuine products and people scanning as well as printing replacement parts that do not conform to OEM specs.

The advances in 3D printing technology has provided counterfeiters with the resources to use increasingly clever ways of recreating products that appear indistinguishable from the genuine ones.

Case in Point: Fake Security Seals

With the help of 3D printing, counterfeiters these days are able to replicate even security seals meant to safeguard cargo inside containers. This wreaks havoc in the supply chain of industries like pharmaceuticals. The fact that such seals can be produced in as little as ten minutes by criminals intent on pilfering cargo, makes this a very potent threat to industries across sectors.

Security Seal Sample (Bolt Seal)

Innovative Solutions to Combat 3D Printed Fakes

NFC Tags/QR Codes

One of the most effective ways of calling out fake 3D printed products is to embed them with NFC tags or QR codes that will help consumers validate their authenticity. Any product or component that does not come with the right code/tag would easily get identified as a fake.

TrackMatriX® Lock on Security Seal

Laser-engraved QR code sample

One can also leverage laser-engraved QR codes containing overt and covert information which can help in product authentication. The patented secure tracking QR code technology is designed to protect against counterfeiting and forgery. Dynamic inspection strategies can be deployed using a dedicated inspection app or using the decryption module for the covert (secret) info reading. Offline verification is also possible.

Matrix-Mark™ Solutions to Foolproof Security Seals

Matrix-Mark™ Taggants can act as the definitive anti-counterfeiting solution that can help secure plastic security seals. Taggants, also known as tracer elements, are physical or chemical markers that can be easily embedded in security seals.

The Matrix-Mark™ covert pigments can be added to the 3D-printing base material. Once the product is printed out, only a proprietary inspection device can help validate the genuineness of the product as the pigments are “super invisible” and cannot be detected by UV or IR.

The taggants can also come with forensic features that can be used as evidence in a court of law. There is an incredibly large number of products which can be enhanced in terms of security and brand protection through the use of these invisible pigments including electronics, pharmaceuticals, casino tokens, injection-molded items, and 3D-printed materials.

Get a FREE CONSULTATION Now!